+91-99127-86599

give me a call

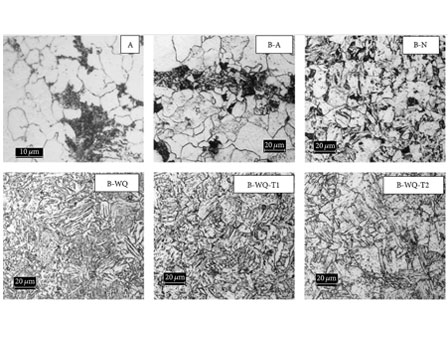

Carbon steel is a steel alloy containing carbon as the main alloying element. Cast alloy steels have been developed to operate under conditions requiring greater pressures, wear resistances, and higher strength with increased toughness and hardenability. The mechanical properties of this alloy are determined by the percentage of carbon present; the higher the percentage, the harder and stronger the alloy becomes through heat treating. Because they can be processed to obtain a wide range of properties, carbon steels are found in a variety of applications.

Both mid carbon and low carbon steel are used for investment casting. Mid carbon steel provides good ductility, strength and wear resistance. It can also be hardened and tempered through heat treatment. Low carbon steel is easily shaped but cannot be strengthened by heat treating. As an alternative, carburizing can be used to increase the alloy’s surface harness.

Low carbon steel contains lower levels of carbon content and is known for its ductility, weldability, and machinability. It is softer and has a lower tensile strength than other steels and is not suitable for heat treatment. Carbon steel casting is typically used for automotive and construction applications.

Mid carbon steel contains medium levels of carbon content and is known for its wear resistance. It is harder than low carbon steel and able to be strengthened using heat treatment.