+91-99127-86599

give me a call

The most important aspect in guaranteeing the reliability of a precision investment cast component is a casting quality verification process that is both meticulous and detail oriented. When rigorous and comprehensive metal casting inspection methods are combined with increased metal casting quality standards, part production quality and performance is enhanced. At Duccan Alloy Castings (I) Pvt. Ltd., we employ world class methods in the inspection of casting to create high performance parts and components.

Duccan Alloy Castings (I) Pvt. Ltd., Offers a wide variety of in-house casting quality control, verification and product testing services (such as NDT) designed to provide our customers with the highest quality cast product. No matter what the intended application, every precision investment cast component is examined, inspected, and approved before leaving our building.

At Duccan Alloy Castings (I) Pvt. Ltd., We provide the following metal casting quality inspection methods to ensure every part and component we manufacture meets our high level of expectation and our customers receive the finest cast parts and components in the industry.

Our casting quality control experts utilize visual techniques to ensure parts are properly filled with metal (no cracking, tearing, holes or voids, non-fill, etc.). They also meticulously inspect each part, making sure there are no distortions or bends before moving forward in the casting quality process. During the final phase of inspection, parts are inspected and compared to the casting quality control plan and written process instructions. Lastly, the casting quality results are documented and stored for future use by production department staff and process engineers.

To confirm the properties of the metal cast part are correct, mechanical testing is performed to approve the metal of the casting. The testing confirms the properties comply per the specified mechanical requirements. The following mechanical properties testing methods are performed to confirm proper casting quality.

Our experts utilize Investment Cast Industry Standards as a guide by setting a range of values the casting dimensions can fall within. We also take into consideration critical part dimensions, given to us by the customer, during the planning and inspection phases. We then verify the dimensions of the parts by using micrometers, thread and plug gauges, CMM machine, and other approved functional gauges. The accuracy of these measuring tools adds to the dimensional consistency and casting quality of the manufactured parts.

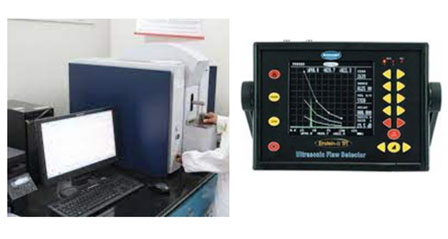

Duccan Alloy Castings (I) Pvt. Ltd., Currently uses Bruker analysis machine [spectrometer] in its metallurgy lab. Before the metal is poured from the melting pot, a sample of molten metal is poured in to a small “coupon” mold and the casting quality is evaluated in the spectrometer. If needed, minor alloying elements are added to the material to bring the alloy melt into required specification. Then another coupon is tested and certified to ensure proper chemical composition.

The chemical composition of every alloy melt is tested and recorded in our database. We then electronically store the records for an indefinite period. This test is performed to ensure the alloy performance properties are to the specification(s) of the customer. Casting alloys are typically specified per ASTM, AMS and SAE alloy specifications.

Duccan Alloy Castings (I) Pvt. Ltd., Performs Non-Destructive Casting Quality Testing (NDT) . This allows us to ensure the quality of a casting without destroying it. Our NDT in-house facility is fully staffed with both Level II technicians. We are also NADCAP Certified in Dye (Liquid) Penetrant Testing, Magnetic Particle Inspection, and Radiographic (x-ray) Inspection. Our on-site NDT facility allows Duccan Alloy Castings (I) Pvt. Ltd., To perform the most common combinations of non-destructive testing and inspection methods required by many high-profile industries, such as Midhani, Cements Plants and Thermal power plant . We utilize the following types of non-destructive inspection methods: