+91-99127-86599

give me a call

Pattern shop with highly skilled workmen for the manufacture of wooden and metal patterns.

Equipped with Hand Moulding, machine Moulding and shell moulding facilities employing Green, Dry, CO2, Resin and Oil Sand Systems.

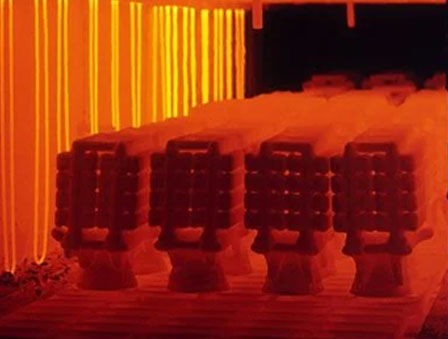

Induction melting furnaces with three crucibles of capacities 0.5MT, 1MT, 2MT with which we can make castings ranging from 25 Kg to 2000 Kg single piece.

Heat Treatment like Annealing, Normalizing, Hardening & tempering, water quenching etc. are carried out continuous type and Batch type in Bogie Heart Type Electric Furnaces of sizes (2.1 mts x 1.4 mts x 1.37 mts),( .6 mts x .6 mts x 1 mts) with Automatic Temperature controllers and Recording facilities.

Our Finishing shop is equipped with pencil grinders welding transformers/rectificer and shot blasting machines.

We are also equipped with proof/final machining with turning and suface grinding facilities. Every piece of metal that shapes at DAC pass through stringent quality assurance checks. Similary, critical inputs like sand, sodium silicate, scrap, ferro-alloys, mould washes, sleeves etc., are subjected to strict quality checks.

Our foundry is backed by modern metallurgical laboratory to monitor the quality right from the raw material stage to achive the desired chemical composition/properties of the products.

Quality control also encompasses metallography, mechanical testing and dye penetrating inspection. Nondestructive test are used when specified or when deemed necessary by our engineering staff to ensure quality requirements of the customers.

Shot blasting is a process that treats metals to remove rust, grease, scale, and other irregularities to create a smooth surface for applying a finishing surface. During this process, some abrasive material is blasted onto the surface and depending on the surface being treated, they may be sand, beads or water. It is important to create a smooth and clean surface to apply the final surface treatment, like powder coating, to the metal surface to achieve a high-quality, beautiful and durable surface treatment. Shot blasting machine is a mechanical method that uses centrifugal wheels to propelling the abrasive to remove surface and other impurities from the surface of steel applications. In general, blasting prior to finishing serves three primary purposes: